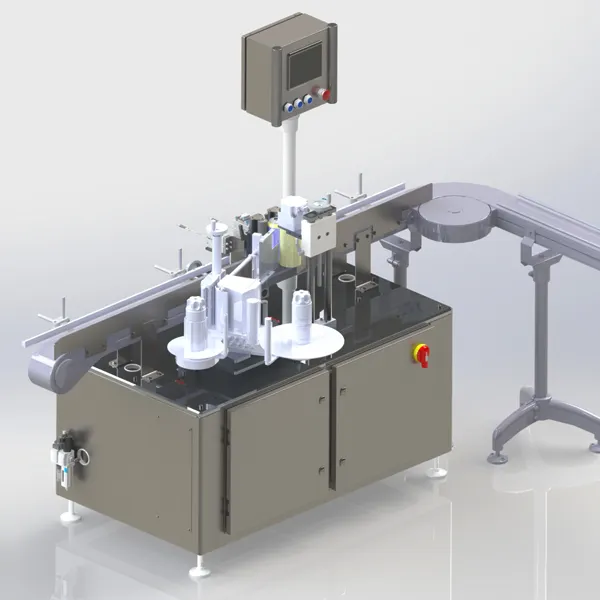

Prism Wrap Labeler

Link Pack

Enhance your product labeling efficiency with Link Pack’s advanced Prism Wrap Labeler, espertly engineered and supported by our local team. Designed with a cutting-edge prism roller system, this labeler guarantees unmatched accuracywhen applying pressure-sensitive wrap-around labels—both clear and opaque—on cylindrical straight wall containers. Easily adaptable to varying output demands, this labeling equipment enables seamless transitions between container formats and labels.

Whether dealing with filled, lidded, or capped containers, our Prism Wrap Labeler delivers exceptional performance. Its continuous conveyor system ensures smooth container transport, while the innovative prism aligner spins containers around their center axis for precise label application.

Built to integrate seamlessly into moderate-speed bottling lines or operate as a standalone unit, this compact yet durable machine boasts a stainless steel closed frame, a Rexroth modular conveyor, Festo pneumatics, and a Herma 500 servo label applicator, delivering consistent and high-performance labeling for diverse packaging needs.

Read More

For added convenience, all electronic parameters are stored in the Allen Bradley PLC, easily accessible and recallable through the user-friendly HMI interface. Elevate your labeling efficiency and accuracy with Link Pack’s Prism Wrap Labeler—your key to precision in labeling technology.The standard working height is 36 inches, but the labeler can be custom designed to fit any production line height, and frames can also be constructed to suit wash-down requirements. Optional equipment includes container orientation, coders, label inspection sensors, and camera reject systems for quality and safety. This straightforward machinery will upgrade labeling precision and efficiency on a wide variety of round containers.

We recommend a slightly different model for labeling conical containers

Category:

Labelers / Alignment / Round Containers