The Value Behind TCO

Total Cost of Ownership Explained

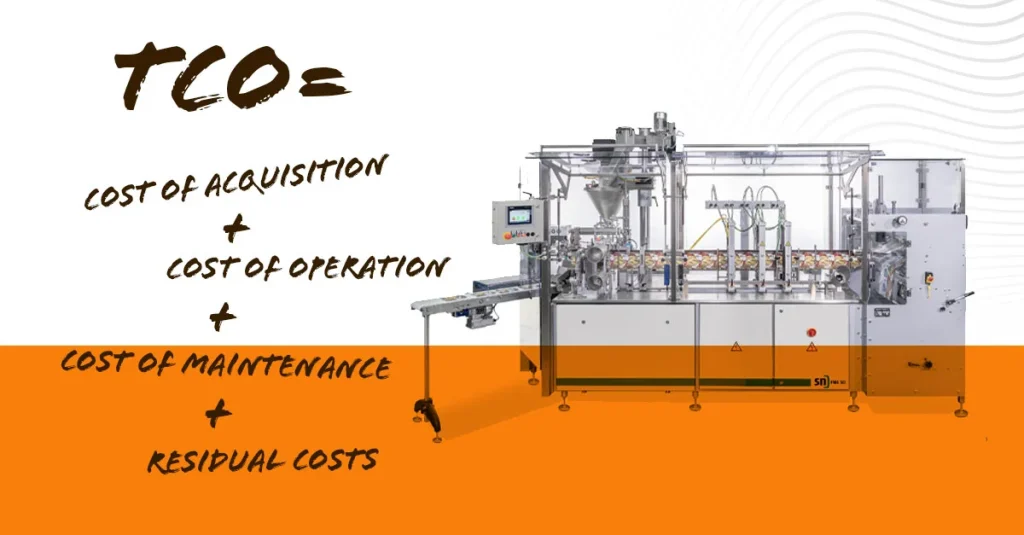

Is TCO on your mind? Well, it should be! Growth means investing into new infrastructure and automated systems to optimize your expansion. Analyzing Total Cost of Ownership or TCO metrics is by far the best way to ensure your business’ assets and finances are well managed. Managers often find themselves persuaded by “bargin” machinery but looking at all angles of an important purchase is paramount to determining all direct & indirect costs that may arise from the first day until it’s last. TCO paints a clearer picture of the positive or negative impact the machinery will truly have on their company. It will also provide the framework necessary to calculate ROI.

Bill Kirwin, an analyst at Gartner, an American consulting and research company, is credited with creating the concept. He defines TCO as “the total cost of acquiring, using, managing and withdrawing an asset over its entire life cycle”. Total Cost of ownership considers CAPEX, OPEX & OEE. Here is a breakdown of each element:

Capex – Capital Expenditure Cost

Capex considers the cost for engineering, Initial investment, commissioning, and start-up costs.

Opex – Operation Expendature Costs

Losses that arise from subsequent maintenance, sanitation, downtimes, changeovers, energy consumption, space occupancy and packaging material consumption.

OEE – Overall Equipment Effectiveness

A calculation of expected vs actual production rates. The formula includes Availability, Performance and Quality OEE=AxPxQ.

Why Packaging Industry Decision Makers are Using TCO

Automation has become an increasingly attractive method to upgrading manufacturing operations. Packaging machinery like Baggers, Labelers and End of Line Machinery can easily cost thousands or millions of dollars which generally prompt decision makers to focus on capital cost. Seeing as many parameters are assessed when making high-risk investments, innovative procurement professionals are opting to use Total Cost of Ownership calculations that make it that much easier have a holistic and accurate picture of expenses and variables that will affect activities and performance in the long term.

Take for example a chocolate manufacturer who is considering a hefty purchase – a new bagging machine. Packaging machinery comes with an impressive price tag and his first instinct may be to seek out used models that seem wise upfront but that would most likely cause many additional expenses – and headaches in the long run!

While there is no exact solution to determine TCO, it is possible to effectively calculate it by considering expenses related to the initial purchase and costs for continued use. The basic equation could be summed up as follows: TCO= Purchase Price + Cost over lifetime. Lifetime costs are determined by different factors and may be calculated in several ways depending on the type of product or service.

Try our ROI Calculator and see your payback timeline instantly!

TCO on Packaging Machinery

Evaluating packaging machine suppliers with different with equipment and price points using a basic Total Cost of Ownership equation will help form a more educated investment and get better buy in from decision makers.

Approaching an investment in packaging machinery with TCO means you are more likely to avoid hidden or unforeseen costs not clearly visible in the negotiation phase. You can use the total cost of ownership calculations well by using it as a comparative tool, a lifecycle assessment tool, and a basis for calculating environmental key performance indicators. Still, at its core, it aids in obtaining greater returns on investment!

Other Blogs of Interest

10 THINGS YOU NEED TO KNOW ABOUT VERTICAL FORM FILL SEAL MACHINE AND SANITATION

Since 1923 – primarily for customers in the food industry — Triangle understands s...

A case for wood pellet processing

The wood pellet sector has accelerated growth in the past five years; according to the WPA...

A Quick Introduction to Food Processing and Packaging

Food processing is a mechanical process that transforms raw ingredients and especially foo...

Automation & Flexible Packaging Seminar 2018

ENGLISH BELOW Groupe Link Pack et son partenaire PPi Technologies Group tiendront ...

Cobots, Our Compelling Manufacturing Allies

Cobots or Collaborative Robots are designed to work in common spaces, in close range with ...

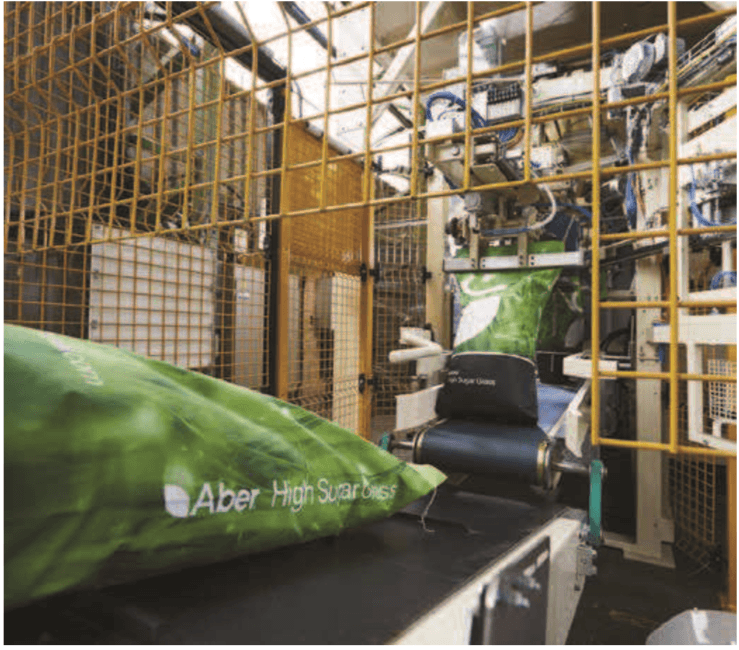

Forage and turf seed processor invest in Concetti automated bagging and palletizing system

Concetti supplies packing line to seed supplier Germinal GB is a leading supplier o...

How versatile is versatile?

I was recently asked this question by an artisan yogurt processor who was in the ma...

Industrial Labeling Machines Boost Vitality

Automated pressure-sensitive industrial labelers have little to no indirect or hidden cost...