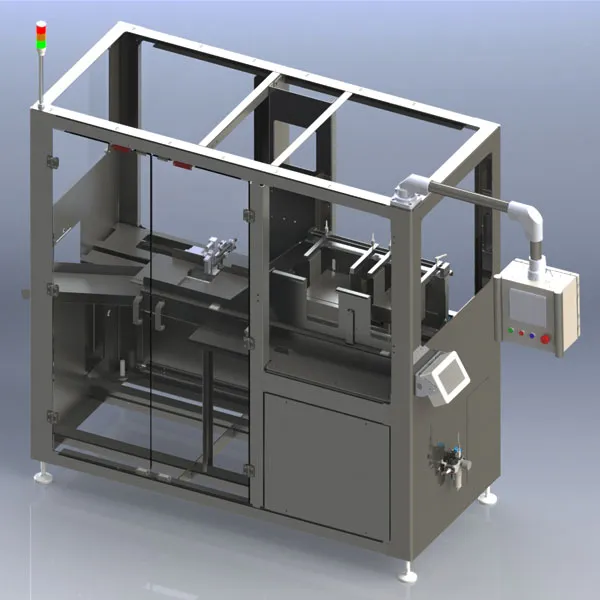

Automatic Pouch Coding System for Pouches & Flat Cartons

Link Pack

Link-Pack’s Automatic Pouch Coding System is a great machine to print variable information directly to pouches, flat cartons and cardboard sleeves of various sizes. Featuring a modular stainless steel frame, an adjustable dual stack magazine, a pick-and-place device and a motorized conveyor, it is ready to integrate any brand of Thermal Ink Jet or Continuous Ink Jet (CIJ) coding system.

This versatile system that can be adapted to many styles of pouches, bags or even branded marketing materials. Operators manually load pouches, cartons or pre-glued sleeves into the dual magazine and the continuous motion lugged conveyor and the side guides ensure proper alignment before reaching the Domino coding printer. The Link Pack Automatic Pouch Coding System can be delivered with an Allen Bradley or Schneider PLC and HMI, which is used to store multiple parameters for quick product changeovers.

Versatile Automatic Pouch Coding System for Accurate Product Labeling & Serialization

Our Automatic Pouch Coding System is considered a stand-alone machine as it is primarily used off-line. Depending on the applications and type of machinery used downstream, it could be integrated to feed directly a pre-made pouch bagger. Otherwise, printed pouches or cartons can be stacked or grouped for further processing.

This Coding System is sharing the same frame as our ELITA Pouch Labeler, thus making the system modular and configurable for different applications. If needed, we can add one or two Herma label applicators to apply product labels or excise tax stamps, as well as a motorized accumulation conveyor. Furthermore, this system can be used for serialization by printing and inspecting information such UDI Codes, QR Codes, Data Matrix, lot numbers or best before dates.

Category:

Coder / Printing