10

Jan

Turnkey Bagging & Palletizing Lines for Animal Feed

Comments

6 things you need to expect when you purchase your next animal feed bagging machinery

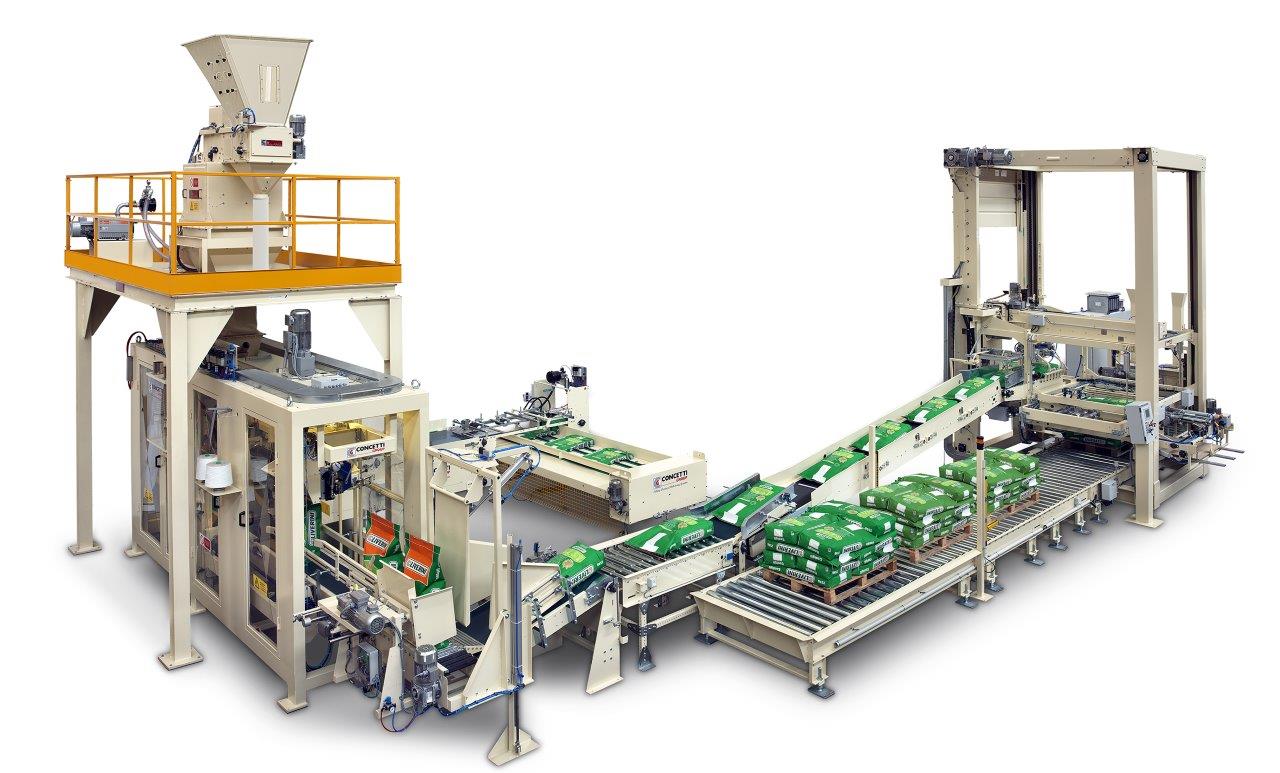

This case study focus on a recent project for the supply of an AUTOMATIC WEIGHING, FILLING, CLOSING AND PALLETISING installation, designed for the handling of Animal feed consisting of wheat, corn, barley and other whole grain.

This customer is bagging products into 25Kg open mouth bags of various dimensions and material, and they want to keep the door open to run different size bags in the future. For free-flowing products, they want to achieve a minimum speed of 550 bags per hour, and for more challenging products, they will run at 480 bph.

Therefore, versatility and quick changeovers were the top criteria during the selection process for this new open-mouth bagger and robotic palletizer.

6 things you need to expect when you purchase your next machinery

Download the Whitepaper!

Fill the form below to access the document