Cups & Tubs Machinery

Our extensive packaging machinery expertise is at your service

Range of machines

At Link Pack Group, we provide a comprehensive range of automated filling and sealing equipment designed for cups, tubs, and trays. To assist you in finding the ideal solution for your product and production needs, we only require some basic information about the material, shape, and size of your open-mouth containers.

We exclusively partner with top-tier OEM manufacturers known for their reputation in packaging innovation. Their proven technology, combined with our integration expertise, ensures you receive reliable performance, seamless project execution, and long-term technical and maintenance support. Our partners continually advance the industry with faster, more efficient machines and smarter designs, helping you remain competitive and ready for the future.

Integrated Systems

Choosing the right cup or tub-filling machine is just one part of the packaging process. To ensure efficiency, every stage – , k Group, we partner with leading OEMs to provide precision fillers, multi-head weighers, and custom dosing systems that integrate seamlessly into your production setup. After filling and sealing, we conduct in-line inspections using metal detectors, x-ray systems, and checkweighers to maintain quality and remove non-conforming products. We also implement coding systems for date and batch marking, along with labeling solutions for product identification. Finally, our complete secondary packaging systems handle carton and tray packing to ensure your products are protected, branded, and retail-ready by the end of the line. With Link Pack Group, you get a comprehensive solution built for performance and quality control!

Machinery for rigid container types

Plastic & Aluminum Cups

Cups, tubs and trays are increasingly popular in today’s market due to their convenience, portion control, and appealing presentation, particularly in the dairy, deli, and ready-meal categories.

To meet the high standards of modern production, Serac offers cutting-edge automatic cup filling machines specifically designed for these rigid containers. Known for their precision, hygiene, and adaptability, Serac’s fill/seal machines and filler cappers ensure accurate dosing with aseptic nozzles for a variety of product textures, liquid drinks, yogurts, other dairy foods, pastes and more. Their machines are engineered for high-speed performance, clean-in-place operation, and quick format changeovers, making them an ideal choice for manufacturers seeking both efficiency and flexibility.

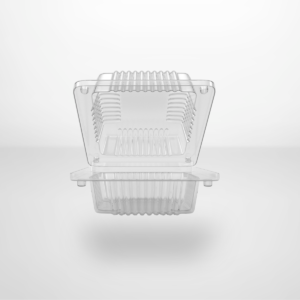

Deli Tubs and Clamshells

Deli tubs and clamshell containers have become popular choices for prepared foods due to their convenience, visibility, and consumer appeal. As production volumes increase and the number of SKUs rises, food processors often find it beneficial to use generic tubs or PET clamshells along with inline label applications. This approach allows for efficient customization of packaging while minimizing the need for pre-printed inventory. To support this process, Link-Pack offers a range of versatile labeling systems specifically designed for conical plastic tubs, trays, and clamshells.

For tubs, we provide top-and-bottom, front-and-back, or full wrap-around pressure-sensitive labelers, which are perfect for achieving a premium appearance on a budget. For clamshells and PET containers, top labeling is the most practical solution because it enables the quick and precise application of branding, nutrition facts, and product details.

Our stand-alone Top Label Applicator is a compact, accurate, and user-friendly upgrade from manual labeling, making it ideal for producers looking to scale up. If your product requires a more distinctive solution, our team is ready to help you select and integrate the best option for your production line.

Plastic, Foils and Paperboard Trays

Trays are an ideal packaging format for a wide range of food products, from ready meals and fresh proteins to salads and snacks, thanks to their versatility, portion control, and compatibility with sealing technologies. Available in materials such as CPET, APET, foil, and eco-friendly paperboard, trays can be single, or multi-compartment, deep-well, or flat, allowing manufacturers to match form with function while enhancing shelf appeal.

To support efficient sealing of these trays, semi-automatic film or foil sealers offer a compact, cost-effective solution for small to mid-sized production lines. With a variety of models and configurations available, Link-Pack helps identify the best system for your tray type, product, and output goals. These sealers handle roll stock film or foil, heat-sealing and die-cutting it to conform to virtually any tray shape.

Options include standard heat sealing, MAP (Modified Atmosphere Packaging), non-vacuum MAP applications, and vacuum skin-pack—each offering specific benefits for product freshness and shelf life.

For high-value or perishable items, such as meats, seafood, and ready meals, vacuum skin packaging provides an extra layer of product protection while maintaining a premium appearance. Rewound waste film also makes disposal and recycling simple, helping you maintain a clean and efficient packaging line.

Deli Tubs, Pails and UN-Type Pails

Deli yub & pail filling is a crucial process in various industries, such as food processing, chemicals, and industrial goods. However, the final step of securing tops & thick plastic lids often becomes a bottleneck. In many semi-automated settings, lids are still applied manually, which can be physically demanding and inefficient. Standard pails as well as UN-Type pails’ rigidity make consistent manual sealing challenging, and increase the risk of injury, inconsistent closures, and production delays.

An lautomatic lid closing machine or a lid placer and closer can effectively address these issues by automating the most physically intensive part of the process. Utilizing a motorized conveyor and overhead roller system, it applies uniform pressure to firmly seal the lids with minimal effort from the operator. Operators simply need to position the lid before the unit automatically conveys and closes it.

This setup significantly enhances ergonomics, speeds up the workflow, and ensures a consistent, secure seal – regardless of the container size or lid type. For facilities that manage larger volumes or adhere to strict packaging standards, automated or semi-automated pail closing solutions are a practical upgrade, reducing strain on workers and maximizing throughput.

Machinery by product type

Dips, spreads, sauces and snacks

Producers with diverse product ranges often face rising costs from printed packaging. A common solution is to use generic containers paired with automated on-line labeling systems. Tubs and clamshells, popular formats for dips, spreads, sauces and snack kits – are well suited to pressure-sensitive labeling systems that offer both branding flexibility and regulatory compliance.

Link Pack manufactures and distributes a variety of Top and bottom, front and back, and wraparound labelers accommodate a wide variety of rigid containers. These systems are well-suited for facilities transitioning from manual to semi automatic machinery or semi-automated facilities ramping up production with fully automated labeling, improving accuracy and line efficiency with a compact footprint.

Dairy and Prepared Meals

Open-mouth containers such as plastic cups and tubs are a staple in the dairy and deli industries but present unique challenges in automation, especially when managing multiple SKUs, hygiene requirements, and leak-proof sealing. These containers demand precise dosing, hygienic filling, and reliable sealing to preserve freshness and protect the product during transport.

Rotary and inline filling machines, compatible with both plastic and aluminum formats, are used for applications ranging from yogurt and hummus to dressings and sauces. Machines are often available in standard heat-seal, induction sealing, or foil-lidding configurations, with options for MAP (Modified Atmosphere Packaging) to further extend shelf life. These systems deliver accurate filling, quick format changeovers, and consistent seal integrity.

Ready Meals, Proteins & Fresh Foods

Tray packaging is one of the most versatile formats for fresh or prepared foods. However, the sealing process can become labor-intensive and prone to errors, depending on the tray material, shape, and type of product. Semi-automatic sealers offer an ergonomic and efficient solution for small to medium-sized operations that need flexibility and control. In contrast, fully automatic thermosealers streamline production for larger operations experiencing rapid growth.

Sealers can be configured for various packaging methods, including heat sealing, modified atmosphere packaging (MAP), or vacuum skin packaging, using rollstock film or foil. They can accommodate trays made from materials such as CPET, APET, aluminum, or coated paperboard, and are capable of cutting and sealing film for different tray shapes and depths. These sealers are ideal for packaging fresh proteins, seafood, and ready-to-eat meals that require extended shelf life and enhanced presentation.