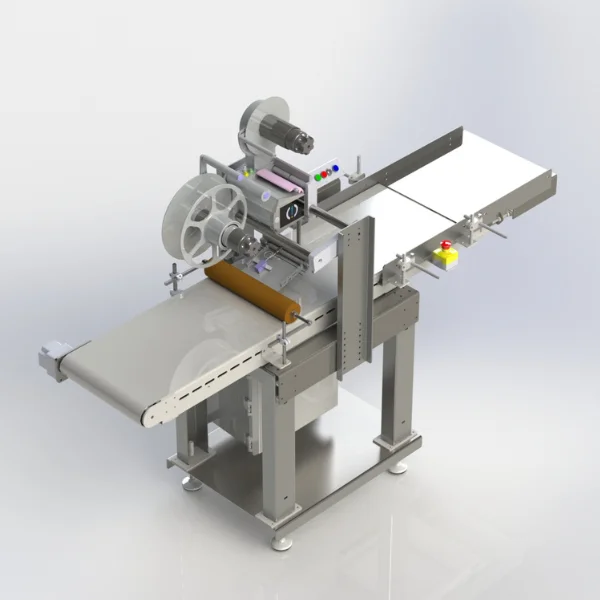

Simple to use and compact in size, this stand-alone labeling unit is ideal for manufacturers and co-packers looking to increase output without committing to a fully automated system.

Our Top Labeler XL includes a large variable-speed conveyor and adjustable guide rails to adapt to a variety of larger bags and pouches. Operators can manually position the pouch on the moving conveyor, activate the labeling cycle and the positioning sensors detect the packaging to ensuring accurate placement regardless of the regularity of packaging infeed.

This labeling system can be used as a standalone solution or integrated to existing upstream or downstream conveyors and machinery. All our labelers feature Herma 500 Servo Label Applicators because of their flexible applications. Coupled with a speed encoder, the Herma Label Applicator will adapt to third-party conveyor speeds and consistently achieve repeatable label placement on your products.