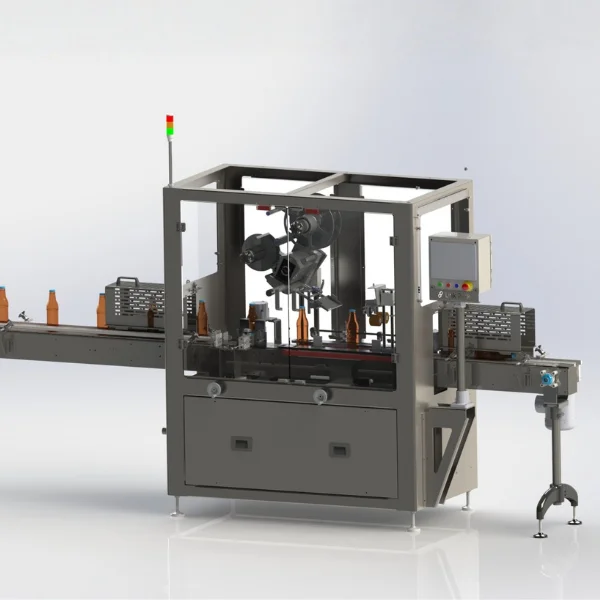

Designed to streamline your production line, this system ensures precise bottle orientation, and labeling at speeds attaining up to 30 bottles/min.

Integrated downstream from the filling machine bottles first travel through, two air knives, powered by a high-speed centrifugal blower to efficiently dry the bottles before orientation & labeling. This ensures optimal adhesion of the tamper-evident label to the bottle surface. The labeler’s motorized prism aligner, consists of a fist position motorized roller and two retractable rollers which work seamlessly to separate and orient the bottles. A camera system, using a specific mark on the body label as a reference point, guarantees accurate and repeatable positioning.

Once precisely oriented, our system transports the bottles gently using motorized side belts, ensuring your labels are applied flawlessly on top of the caps, with both flaps neatly wiped down. This process minimizes the risk of scuffing or damaging your body labels, ensuring a pristine final product.