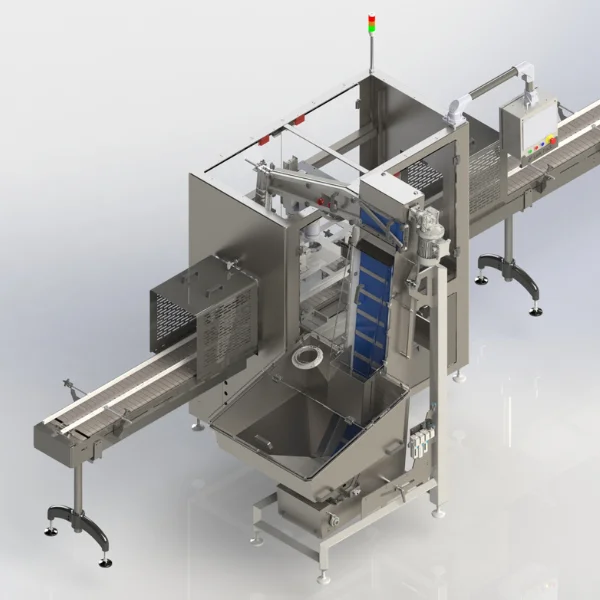

This capper is particularly well-suited for numerous plastic jars and JIBs (Intermediate Bulk Containers) filled with edible oils, providing an efficient screw capping solution that ensures consistent performance at speeds ranging from 8 to 12 bottles per minute.

The system incorporates a fully integrated cap sorting elevator that is compatible with a wide variety of cap styles, allowing for smooth and efficient cap placement and tightening. The torque-controlled capping head is engineered to provide precise sealing, adjusting automatically to ensure that each cap is securely fastened without damaging the container or the cap itself. This feature guarantees uniform sealing across all products, which is critical for maintaining product integrity. This automatic capper is specifically built to support expanding edible oil or other liquid production lines that demand high levels of precision, hygiene, and reliability.