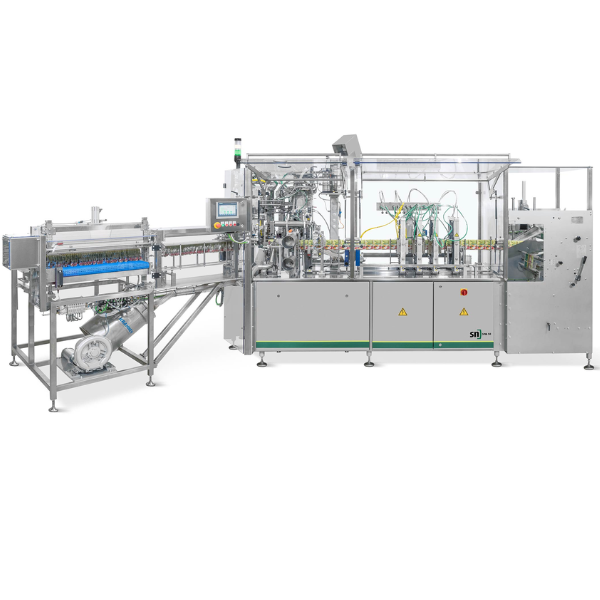

SN Pouch-Pack SPM 50

The SPM 50 from SN Maschinenbau is a compact HFFS spouted pouch bagger designed for efficient production of spouted stand-up pouches. With speeds of up to 70 pouches per minute and a small footprint, it helps manufacturers boost output while saving valuable floor space.

By producing pouches directly in-house, this horizontal form-fill & seal machine reduces reliance on external suppliers, lowers storage and logistics costs, and improves overall cost per pouch. It supports a wide range of formats, from 3-side and 4-side sealed to bottom-fold and center-spout stand-up pouches. Compatible with recyclable mono-material films, it also supports sustainable packaging goals without sacrificing performance.

For food, beverage, and non-food industries alike, the SPM 50 pouch bagger offers speed, flexibility, and sustainability in one machine. Partnering with Link Pack ensures local support, fast integration, and tailored solutions to make your packaging line more competitive.

Instant Benefits

Category:

Bagger / FFS / Spouted Pouch Bagger