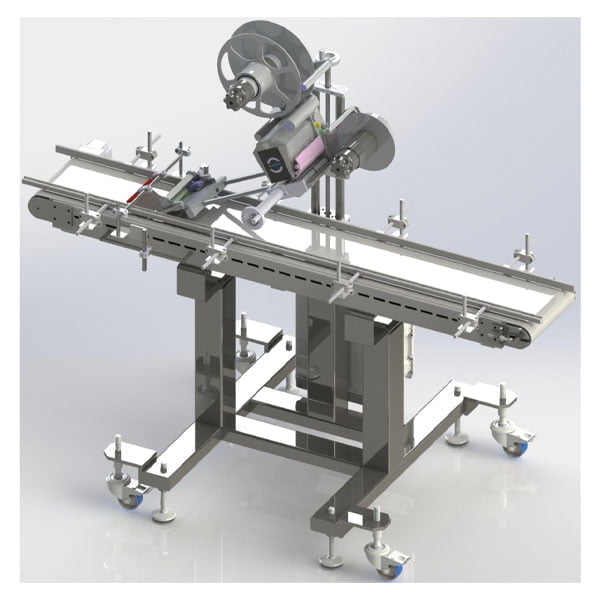

Hand-Fed Pouch Labeling Machine

Link Pack

Our Hand-Fed Pouch Labeling Machine is one of the most compact labelers on the market. This model can be custom designed to fit your existing production line or work offline with efficiency. This labeler will allow you to apply labels to pouches destined to be filled with various products, including cannabis flowers, cannabis gummies, candy, snacks and other edible products with high accuracy and repeatability.

Our Top Labeler includes a variable-speed conveyor (as shown in the picture) but it can also be built without a conveyor to let you install the labeler over your existing conveyor. Our range of stand-alone labelers feature Herma 500 Servo Label Applicators which are modular, easy to use and offer flexibility for various applications. Optical sensors detect the pouch to label, ensuring a consistently placed label regardless of the regularity of packaging infeed.

Read More

Label changeovers, pouch size and speed adjustments are all designed to be intuitive. Optional locking wheels (casters) are available to let you move the machine away from your production area when you don’t need it.If you need a labeler for clamshells, food trays, tubs, or cartons, please take a look at our Top Labeler

Category:

Labelers / Top / Flexible Packaging